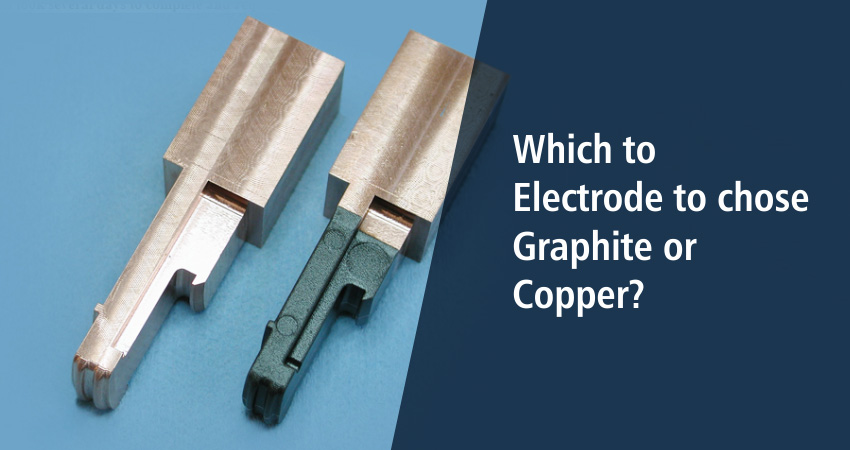

When it comes time to decide whether to use graphite or copper electrodes in your shop, it’s important to look at the big picture. One has to consider application for which EDM is going to be used, depending on which a type of electrode can be chosen.

Earlier, Copper was the only option available, however with more availability of Graphite and its grades, use of Graphite for electrodes has increased substantially in last few years.

In this blog, we going to take a look at advantages and disadvantages of both which will help you decide which is the best fit for your needs.

Advantages of graphite electrodes

Graphite comes with lot of advantages. Sold by the grade, machining graphite is very easy. It can be cut, drilled, grind, to whatever size and shape we need. Graphite can drill cut up to three times faster than copper and provides excellent surface finishes.

Another huge advantage of graphite is no burrs are produced in its machining. The graphite material can be machined on a high-speed mill and its easier to cut out complex shapes and forms. Most importantly, once the material is cut, no post processing is required.

Graphite has very high melting point which results in less wear. Moulds could be cut with one or two electrodes on a CNC EDM machine with very little wear.

Disadvantages of graphite electrodes

If your EDM is old than you might at times find graphite dust particle on the floor or near by machines. However, the newer high speed machines do not face this problem. Another important point is the finish on the graphite should be as good as you need in the mould. If there are to many wear marks on graphite than they tend to get reproduced on the mould.

Advantages of copper electrodes in EDM Machining

The biggest advantage of copper is mirror like surface finish. However, this requires the copper to be machined using CNC Machine with the right setting and perfect flushing techniques. This is especially useful in smaller cavities or the one with complex geometrical shapes that are relatively difficult to polish.

Also, Copper tends to work better for EDM machining even if the flushing system is poor. If an eroded part is not flushed it may be possible to get a non-pulsating, direct flow of current from the electrode to the work piece, With copper electrodes such instances are arrested.

Disadvantages of copper electrodes

Copper is a hard metal, as compared to graphite. Copper also has very low heating point. With quick heating copper electrodes develop a tendency to stick or melt. Another disadvantage, as compared to graphite electrodes is creation of burr. No matter what precautions you take, copper electrodes in most instances will need to undergo a deburring process.

Conclusion

Copper and graphite electrodes come with their own set of advantages and limitations. The decision to choose the right kind of electrode must be taken only after a careful consideration of speed and finishing requirements to machine the material safely.