Surface finish in very important aspects when it comes moulds in particular, as product coming out from mould is typically a mirror image of mould itself. If the mould has any particular ‘lays’ it will directly have opposite impression on product.

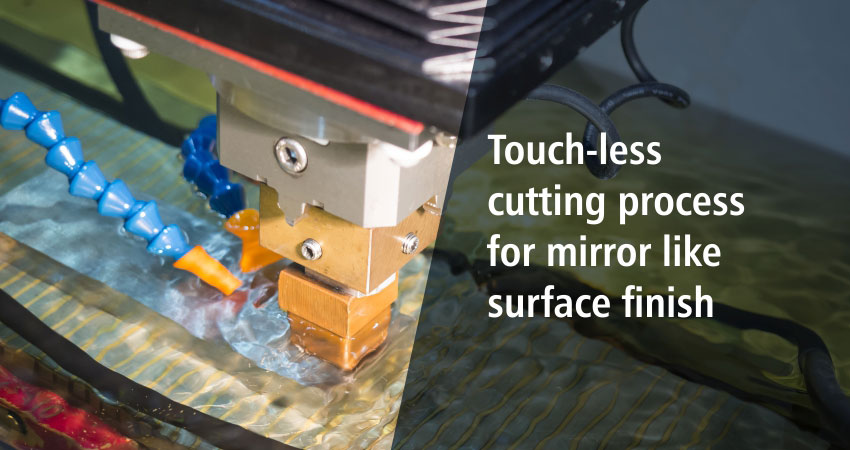

An EDM surface finish is different to that produced by conventional machining. Cutting processes produce a finish with directionality. This is determined by the movement of the cutting tool. Typically all drilling or cutting processes create slight unevenness on the product However, with EDMs touchless cutting process mirror like surface finish is possible.

Erosion rather than cutting

EDM actually does not cut any workpiece, it actually erodes the material from it. EDM works by creating arcs of electricity between the tool and workpiece. As each arc touches the workpiece intense heat and pressure vaporizes material and blasts it from the surface, leaving behind a small pit.

Removed material is taken away by dielectric fluid from the tank, EDM is unaffected by material hardness. This means a range of exceptionally hard and tough materials are machine able.

EDM finish quality

In conventional drilling or cutting, surface finish is exact mirror of cutting agent. As EDM erodes the material it provides better finish. and key to it is slower cutting with multiple runs.

When there is requirement of super finish quality, usual practice should be high-speed roughing cut with one or more finishing – skimming. i.e. One pass for cutting and 2 – 3 passes for skimming to achieve the required finish.

The Advantage EDM

An EDM surface finish is different to one produced by conventional material removal processes. Rather than exhibiting directionality, the texture is random, which is beneficial in many applications. Furthermore, by taking multiple skimming passes, EDM finish quality can become almost mirror-like.