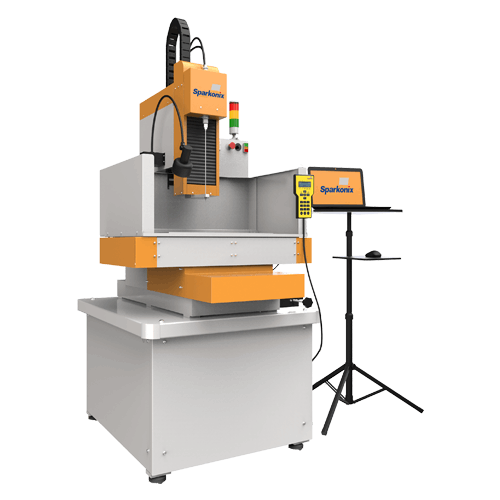

CNC EDM DRILL

CNC EDM Drill

High speed drilling for small holes

| Electrode pipe Diameter | 0.3 to 3.0 mm |

| Max Drilling Depth | 300 mm |

| Work table size ( L X W ) | 600 x 450 mm |

| Travel -X axis | 450 mm |

| Travel – Y axis | 350 mm |

| Travel – Z axis | 300 mm |

| Travel – W axis | 230 mm |

Specifications

| Daylight | 310 mm |

| Shut Height | 80 mm |

| Throat | 185 mm Min to 535 mm Max |

| Measuring system | Absolute Encoder |

| X ,Y & Z axis feed rate(max) | 1000 mm/min |

| Resolution of X,Y & Z axes | 5 µm |

| Maximum work piece weight | 600 Kg on machine table |

| Maximum work piece height | 300 mm |

| Power supply | AC 415 V±10%, 50HZ ±5%, 3 Phase |

| KVA | 5 KVA |

| Net weight of the Machine | 2300 kg |

| Machine Floor Area | 2300 X 2000 mm |

Mechanical Features

- Robust construction with FG 260 Cast structures

- Deformation free machine with stability and accuracy

- Better flatness and wear resistance to avoid scratching with Granite T–Slot table (Grade Zero) for placement of work piece

- High sensitive & fast response with, form and fit Linear motion Guide ways with AC servo system for X,Y, Z, W axis

- Accurate positioning and repeatability owing to precision ball screw with pre-loaded angular contact Bearings, supported at on both ends

- Compact controller with interchangeable insert-Card type design

- Built in safety features such as software, hardware and mechanical limit switch

- Intelligent arcing sensor for auto adjustment of functional parameters

- Indigenous high pressure direct drive Plunger Pump, with stainless steel body, controlled by solenoid valve

- Effective debris removal with additional wash away port near drilling point

CNC Controller

- Siemens 828 D Dedicated control unit

- Controlled/Programmable Axes : Standard X,Y,Z,W

- Simultaneous controlled axes : X,Y,W

- Monitor: High quality 10.4” TFT color display

- I/O of programs & data transfer: Ethernet,USB port & CF card

- Minimum programming increment: 1 µm

- Program/Data store capacity: 3 MB

- Electronic hand wheel : For manual axes movement

Technical Specifications (Machine Tool)

| Parameter | Unit | Speed II CNC (3 Axes) | Speed III CNC (3 Axes) | Speed VII CNC (3 Axes) |

| Electrode Pipe Dia. | mm | 0.3 to 3.0 | 0.3 to 3.0 | 0.3 to 3.0 |

| Max. Drilling Depth | mm | 300 | 300 | 300 |

| Work Table Size | mm | 550 (L) x 350 (W) | 600 (L) x 450 (W) | 800 (L) x 500 (W) |

| Travel X axis | mm | 350 | 450 | 800 |

| Travel Y axis | mm | 250 | 350 | 500 |

| Travel Z axis | mm | 300 | 300 | 300 |

More Info

| Parameter | Unit | Speed II CNC (3 Axes) | Speed III CNC (3 Axes) | Speed VII CNC (3 Axes) |

| Travel W axis | mm | 250 | 230 | 250 |

| Daylight | mm | 340 | 310 | 535 |

| Shut Height | mm | 90 | 80 | 285 |

| Measuring System | Incremental | Incremental | Incremental | |

| All Axes Feed Rate (Max) | mm/min | 1200 | 1200 | 1200 |

| Resolution of X, Y and Z axis | μ | 5 | 5 | 5 |

| Max. Workpiece Weight | Kg | 350 | 600 | 2000 |

| Max. Workpiece Height | mm | 310 | 300 | 510 |

| Power Supply | AC 415 V, 50 Hz,3 Phase | AC 415 V, 50 Hz, 3 Phase | AC 415 V, 50 Hz, 3 Phase | |

| Connected Load | KV | 5 | 5 | 5 |

| Net Machine Weight | A | 1000 | 2300 | 2000 |

| Machine Floor Area | Kg | 1500 x 2200 | 2300 x 1800 | 1500 x 2200 |

| Dielectric | mm | Tap Water at Max.100 kg/cm² | Tap Water at Max.100 kg/cm² | Tap Water at Max. 100 kg/cm² |

| Automatic Filtration System | Optional | Standard | Standard | |

| Operating Console | Laptop | Laptop | Laptop | |

| Programming Software | EDM CAM | EDM CAM | EDM CAM |

Features

- FG 260 Cast Structures

- LM Guideways with AC Servo System for X, Y, Z Axes

- Ball Screws with pre-loaded angular contact bearings

- Better Flatness and Wear Resistance with Granite T-Slot / SS Table

- High Pressure Direct Drive Plunger Pump, with SS body