METAL ARC DISINTEGRATOR

Ideal for removing

- Broken tap/drill

- Makind slots

- Holes in wear plates

- Seized, frozen, rusted bolts

- Seized tools

Metal Arc Disintegrators was among the first line of products developed by Sparkonix and continues to be the preferred, one-stop shop for providing flexible solutions to remove broken tap/drill.

SK III

Easily remove broken tap/drills

| Power | 3 KVA |

| Electrode Movement | 150 mm |

| Work Table | 700 X 600 mm |

| Max. Distance | 320 mm (Table and Electrode holder) |

| Job Height from floor | Up to 1050 mm |

| Coloumn Height | 750 mm |

More Info

Specifications

| Power Supply | 415 V, 3 Phase, 50 Hz |

| Max. Height of Cross Arm | NA |

| Cross Arm Motorised Vertical Travel | NA |

| Distance – Coloumn and Electrode | Min 280 mm Max 280 mm |

| Length of Cross Arm | NA |

| Horizontal Travel of Electrode | NA |

| Swiveling Movements | NA |

| Servo Slides | 360 deg |

| Cross Arm Vertical Coloumn | 360 deg |

| Coolant | Tap Water |

| Coolant Pump Capacity | 10 LPM |

| Coolant Tank Capacity | 50 Liters |

| Machine Floor Area | 760 X 1000 X 1920 mm |

SK - DMS Series

( Heavy duty Series , Portable on wheels )

Easily remove broken tap/drills

| Machine Tool | SK III | DMS X | DMS XX |

| Power Rating (KVA) | 3 | 10 | 20 |

| Electrode movement (mm) | 150 | 200 | 250 |

| Work Table (mm) | 700×600 | 1050×750 | 1050×750 |

| Max. Job Height (mm) | 1050 | 1750 | 1750 |

| Column Height (mm) | 750 | 1250 | 1250 |

Swivelling Movements Servo Slides Cross Arm Vertical Column | NA 360 deg 360 deg | 35 360 deg 360 deg | 35 360 deg 360 deg |

| Coolant pump capacity (LPM) | 10 | 10 | 10 |

Electrode Suitability

Type of Electrodes: Copper Tubes, Tungsten, Copper and Graphite

Max. Distance between machine unit and job with portable head to remove broken tap/drill (optional) – 15 meters

DMS X

Easily remove broken tap/drills

| Power | 3 KVA |

| Electrode Movement | 150 mm |

| Work Table | 700 X 600 mm |

| Max. Distance | 320 mm (Table and Electrode holder) |

| Job Height from floor | Up to 1050 mm |

| Coloumn Height | 750 mm |

More Info

Specifications

| Power Supply | 415 V, 3 Phase, 50 Hz |

| Max. Height of Cross Arm | 900 mm |

| Cross Arm Motorised Vertical Travel | 700 mm |

| Distance – Coloumn and Electrode | Min 280 mm Max 650 mm |

| Length of Cross Arm | 850 mm |

| Horizontal Travel of Electrode | 350 mm |

| Swiveling Movements | 35 deg |

| Servo Slides | 360 deg |

| Cross Arm Vertical Coloumn | 360 deg |

| Coolant | Tap Water |

| Coolant Pump Capacity | 10 LPM |

| Coolant Tank Capacity | 100 Liters |

| Machine Floor Area | 1380 X 950 X 2500 mm |

DMS XX

Easily remove broken tap/drills

| Power | 3 KVA |

| Electrode Movement | 150 mm |

| Work Table | 700 X 600 mm |

| Max. Distance | 320 mm (Table and Electrode holder) |

| Job Height from floor | Up to 1050 mm |

| Coloumn Height | 750 mm |

More Info

Specifications

| Power Supply | 415 V, 3 Phase, 50 Hz |

| Max. Height of Cross Arm | 900 mm |

| Cross Arm Motorised Vertical Travel | 700 mm |

| Distance – Coloumn and Electrode | Min 280 mm Max 650 mm |

| Length of Cross Arm | 850 mm |

| Horizontal Travel of Electrode | 350 mm |

| Swiveling Movements | 35 deg |

| Servo Slides | 360 deg |

| Cross Arm Vertical Coloumn | 360 deg |

| Coolant | Tap Water |

| Coolant Pump Capacity | 10 LPM |

| Coolant Tank Capacity | 100 Liters |

| Machine Floor Area | 1380 X 950 X 2500 mm |

Suitable Electrode sizes and approximate time taken in minutes for disintegrating Broken Tools (Length of Broken Took 25 mm)

| Tap / Drill (mm) | Electrode Size (mm) |

Time in Minutes

|

||

| SK III | DMS X | DMS XX | ||

| 2.6 | 1.5 | 5 | 4 | 2 |

| 4.0 | 2.0 | 6 | 5 | 3 |

| 6.0 | 3.0 | 8 | 5 | 3 |

| 8.0 | 5.0 | 9 | 7 | 4 |

| 10.0 | 6.0 | 11 | 8 | 4 |

| 12.0 | 7.0 | 14 | 10 | 5 |

| 14.0 | 8.0 | 18 | 12 | 6 |

| 16.0 | 10.0 | 22 | 14 | 7 |

| 18.0 | 11.0 | 25 | 15 | 8 |

| 20.0 | 12.0 | 30 | 18 | 9 |

| 27.0 | 15.0 | 38 | 20 | 10 |

| 35.0 | 20.0 | 50 | 25 | 13 |

| 40.0 | 25.0 | 60 | 30 | 15 |

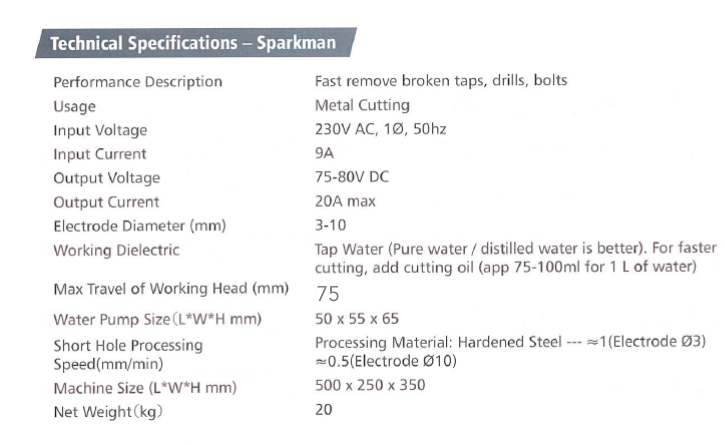

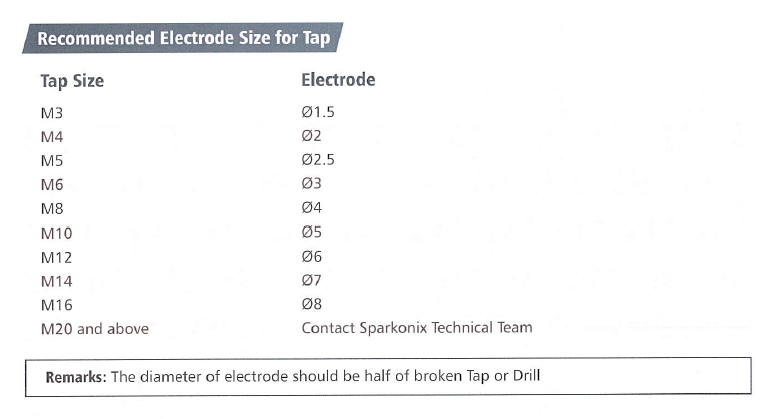

SPARKMAN

( Portable just by Hand)